The carbon capture system

A team led by a Johns Hopkins doctoral candidate has developed a new technique using electricity to drive a chemical process that removes climate-damaging carbon dioxide from the air. They describe their approach, which unlike many previous electrochemical carbon capture methods operates in the presence of oxygen, in Nature Energy.

Andong Liu

“Carbon capture technologies that use thermal chemistry are well developed and some have already been commercialized, but those methods are pretty energy consuming. When your method for capturing carbon is driven by electricity, you don’t use nearly as much energy,” said study leader Andong Liu, who worked with colleagues at Johns Hopkins Whiting School of Engineering and California Institute of Technology on the research. “However, there have also been some limitations of the existing electricity-driven carbon capture systems that our method has managed to nullify, which is exciting.”

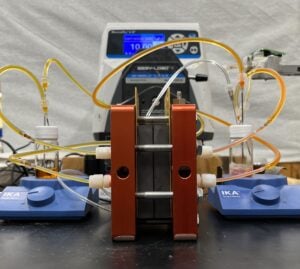

The researchers’ carbon capture system works like a sponge that can be turned on and off using electricity. It consists of two parts. The first—and main part—consists of a flow cell with carbon paper electrodes and a Nafion membrane, which is a membrane that is used to selectively transport cations (positively charged ions) while preventing electron conduction. The Nafion membrane is sandwiched between the cathode and anode, which receive and release electrons during an electrochemical reaction.

The second part is the carbon dioxide sorbent system, comprising two liquid tanks containing two chemical solutions—a catholyte and an anolyte— that are continuously circuited through the flow cell by a pump. The cathode electrolyte is a mixture of azobenzene, butanol, and supporting salt, which is used to capture carbon dioxide. While the anolyte is a mixture of ferrocene and supporting salt to balance the electrons of the system. There is also a carbon dioxide sensor that records the concentration changes during carbon capture and release.

When an electric current is applied, the system turns on, triggering the organic molecules in the catholyte to grab carbon dioxide from the feed streams, like air or flue gas.

Liu said the system improves upon one of the major flaws of many previous carbon capture technologies that rely on electrochemistry, which is the sensitivity of the sorbents towards oxygen in the air.

“In traditional electrochemical carbon capture methods, the molecules used can break down when they contact oxygen,” Liu said. “Our new method uses a form of alcohol to stabilize those molecules, which makes the system more efficient and less prone to oxygen damage.”

Though the system has only been tested in a lab, Liu believes it has the potential to be scaled for use in dry climates because it doesn’t rely on the use of water.

“The thought is you could build a larger version of what we have in the lab and put it near factories in dryer climate to capture the carbon they’re emitting,” Liu said. “These areas have struggled to utilize carbon capture technologies because of how essential water is to them. Our method could change that, which would really help in the fight against climate change.”

Among the co-authors of the study is Yayuan Liu, assistant professor of chemical and biomolecular engineering and associate faculty member with the Ralph O’Connor Sustainable Energy Institute (ROSEI).