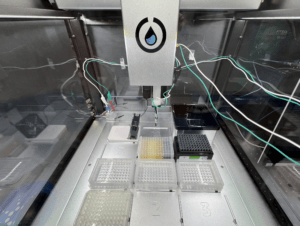

A team of Hopkins researchers has created an automated platform that could speed up the search for better materials for renewable energy storage. The system combines electrochemistry, artificial intelligence, and robotics to rapidly test and analyze electrolytes—the liquids or gels that transport charged particles in batteries—helping scientists identify better batteries much more quickly.

Dian-Zhao Lin

Though most of the group’s work has focused on zinc metal batteries, its new approach could be applied across all types of metal batteries, such as lithium-ion, sodium-ion, magnesium, and others, said team leader Dian-Zhao Lin and a postdoctoral fellow in the Whiting School of Engineering’s Department of Chemical and Biomolecular Engineering.

“Our platform can test hundreds of formulations in days rather than months using traditional trial-and-error methods,” Lin said. “For example, it can test the cyclic voltammetry – which measures the current that develops in an electrochemical cell – of 96 different electrolyte formulations in just three hours, while conventional testing would require a full day of continuous work to do the same job. That’s eight times faster.”

The team’s results appear in Science Advances.

The early stages of this two-year project, supported by the Ralph O’Connor Sustainable Energy Institute (ROSEI), focused on designing microelectrode bundles, establishing automated protocols, and validating the reliability of the system. Once the working platform was created, the researchers began to integrate machine learning capabilities to help predict zinc metal battery electrochemical performance, discover new electrolytes for high-performance batteries and uncover property-performance correlations.

The result is an affordable and customizable high-throughput experimentation platform that dramatically accelerates electrochemical research.

“Techniques that rapidly test large numbers of samples in parallel—known as ‘high-throughput methods’— have revolutionized fields like pharmaceutical chemistry and materials science, but their implementation in electrochemistry has been limited due to technical challenges and cost barriers,” Lin said. “Our platform avoids those technical issues and uses off-the-shelf components with custom 3D-printed parts. This makes it very affordable so research labs that don’t have enormous budgets can use it.”

The automated platform that could speed up the search for better materials for renewable energy storage

The automation aspect of the system is a major achievement because it solves a common problem with traditional high-throughput systems – the challenge of reproducing exact conditions for multiple tests happening at the same time. When humans operate these systems, small unintentional differences in technique can lead to significantly different results. The group’s system being automated eliminates this issue, ensuring consistency.

“Because is it consistent, our new platform generates more reliable data,” Lin said. “This standardization leads to more robust scientific conclusions and accelerates real progress rather than spending time troubleshooting inconsistent results.”

Lin and the team plan to expand their platform’s use to other areas, including as fuel cells, electrolyzers, and CO₂ reduction. He believes that any field relying on high throughput experimentation can benefit.

“The possible combinations of electrolyte components are virtually infinite, and traditionally we’ve explored this space through intuition and trial-and-error,” Lin said. “By combining high-throughput experimentation with automation, we’ve created a systematic approach to navigate this vast chemical space efficiently, leading to discoveries that might otherwise have been missed.”

Lin works in the laboratory of Yayuan Liu, a Russell Croft Faculty Scholar and assistant professor of chemical and biomolecular engineering who is also an associate researcher with ROSEI.